Waterproofing cement is a specialized type of material designed to enhance the resistance of concrete structures to water penetration. It is formulated with additives and admixtures that improve the water-resistant properties of conventional cement which makes it suitable for applications that require protection from water. This cement variety has become a vital role in today’s construction industry as it helps maintain the integrity and longevity of concrete structures by minimizing the detrimental effects of water penetration.

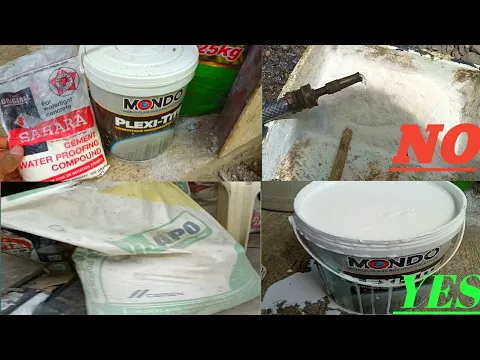

Water Proofing Cement Prices

The most commonly used waterproofing cement in the Philippines is Sahara Cement Waterproofing, with an average price ranging from ₱38.00 to ₱59.00 per 908 grams.

Advantages of Water Proofing Cement

Water Resistance – The primary advantage of waterproofing cement is its ability to enhance the water resistance of concrete structures which can prevent water penetration and other moisture-related problems such as dampness, mold growth, and the deterioration of structural components.

Versatility – The waterproofing cement can be applied to various construction structures such as foundations, basements, roofs, and water tanks providing them versatile protection against water damage.

Easy Application – Waterproofing cement is easy to apply, whether as an admixture during concrete mixing or as a surface coating on existing structures.

Protection Against Corrosion – With the help of its water-resistant properties, waterproofing cement can also help protect the reinforcing steel from corrosion and degradation of the structural frameworks.

Disadvantages of Water Proofing Cement

Cost – Waterproofing cement can be more expensive than traditional cement which leads to higher upfront costs in construction projects. This area might need consideration if your project’s budget is limited.

Installation Complexity – If you want to achieve optimal results with waterproofing cement can require skilled labor because improper installation can compromise the waterproofing cement’s effectiveness. In addition, proper surface preparation is also important for the success of waterproofing cement, and if this step is neglected, it can also lead to reduced cement’s effectiveness.

Limited Repair Options – Once applied, repairs to a waterproofing cement can be difficult, and fixing issues can require a lot of effort.

Compatibility Concerns – Compatibility with other construction materials and existing structures must be considered to avoid potential issues. You must make sure that when you add the waterproofing cement to the mixture, the other materials in it are compatible.

Video of Water Proofing Cement

FAQs

Which cement sussed for waterproofing?

The most common type of cement used for waterproofing is the Ordinary Portland Cement of grade 43 or 53.

What is the best waterproofing cement?

The best waterproofing material for cements is the silicone sealant which is a type of adhesive in liquid form.

What can I mix with cement to make it waterproof?

You can enhance the waterproofing of the mixture by adding Cementmix, similar to the way you would add water, to ensure comprehensive and permanent waterproofing.

What is the mixture for waterproofing cement?

For an effective waterproof mix, it is important to start with dense concrete characterized by minimal pores to achieve a low water-to-cement W/C ratio, ideally below 0.5 for optimal results.

What is the strongest waterproofing?

Polyurethane stands out as the best waterproofing material, as it can be applied seamlessly and in addition, it can penetrate the surface deeply and evenly.