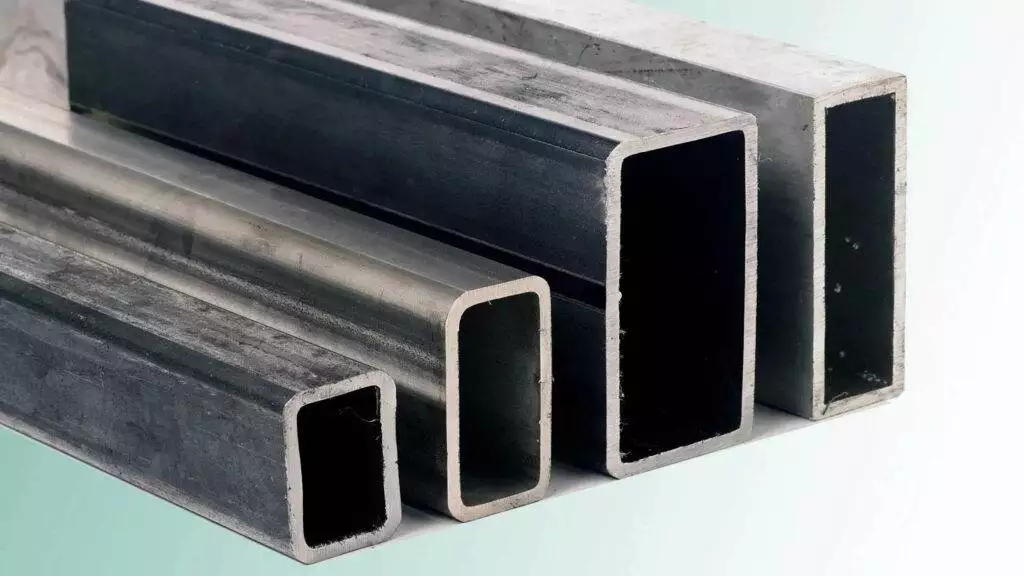

Tubular Steel refers to a variety of steel product that has a hollow cross-section that takes the form of a tube. It is commonly used in various applications in different industries such as construction, manufacturing, and infrastructure. Lastly, this type of steel is known for its versatility and strength, offering structural support while also allowing the efficient use of other materials.

Tubular Steel Prices

Tubular Steel prices vary depending on its size and dimensions, however, on average, this tube is priced at ₱244.00 per unit and could go up to ₱493.00 per unit.

| Item no. | Description | Size/Dimension | Length | Price per Unit |

| 1 | B.I. (Black Iron) Tubular | 20mm x 20mm x 1.0mm thick | 6 meters | ₱244.00 |

| 2 | B.I. (Black Iron) Tubular | 25mm x 25mm x 1.0mm thick | 6 meters | ₱325.00 |

| 3 | B.I. (Black Iron) Tubular | 32mm x 32mm x 1.0mm thick | 6 meters | ₱456.00 |

| 4 | B.I. (Black Iron) Tubular | 50mm x 25mm x 1.0mm thick | 6 meters | ₱443.00 |

| 5 | B.I. (Black Iron) Tubular | 50mm x 50mm x 1.0mm thick | 6 meters | ₱493.00 |

Advantages of Tubular Steel

Strength and Structural Integrity – Tubular Steel provides high strength and structural integrity which makes it suitable for applications where the required load-bearing capacity of the materials is important.

Lightweight – When compared to solid steel with the same strength, tubular steel is often lighter, which makes it easy to handle, transport, and install.

Corrosion Resistance – Tubular Steel can also exhibit resistance to corrosion when treated right and the right coating is applied. The corrosion resistance enhances the material’s durability and longevity making it usable outdoors or in harsh environments.

Cost-Effective – The efficient use of material, ease of fabrication, and reduced weight can contribute to the cost-effectiveness of tubular steel in construction and manufacturing.

Ductility – The good ductility of the tubular steel allows it to be able to distort its shape under stress without fracturing. This property can be advantageous in certain structural applications.

Disadvantages of Tubular Steel

Higher Initial Cost – Tubular steels have a higher initial cost when you compare them to some other materials. This aspect needs a lot of consideration, especially in projects where the budget is limited.

Welding Challenges – Welding tubular steel could pose a lot of challenges. Specialized welding techniques or equipment are required for optimal results which could also add to the overall project cost.

Potential for Corrosion – Without proper coatings or treatments, tubular steel could become prone to corrosion, especially in environments with high humidity or exposure to corrosive substances.

Limited Availability in Certain Sizes – In some cases, obtaining specific sizes or shapes of tubular steel is hard depending on regional availability and manufacturing capabilities. This could become a problem when a project requires a specific shape for a certain application.

FAQs

What is tubular steel?

Tubular steel is a kind of material made from steel in the shape of a cylinder, a tube-shaped steel.

What is tubular steel used for?

Steel tubing could be used in different applications throughout many industries, particularly for the transportation of water, gasses, and liquid wastes.

What are the benefits of tubular steel?

One benefit of tubular steel is its high tensile strength. This attribute provides the tube resistance to both internal and external stress making it usable in any application.

Is tubular steel expensive?

Tubular steel is easily and quickly made, making it affordable.

Is tubular steel durable?

Tubular steel is made from galvanized steel giving it mechanical stability and good impact resistance.