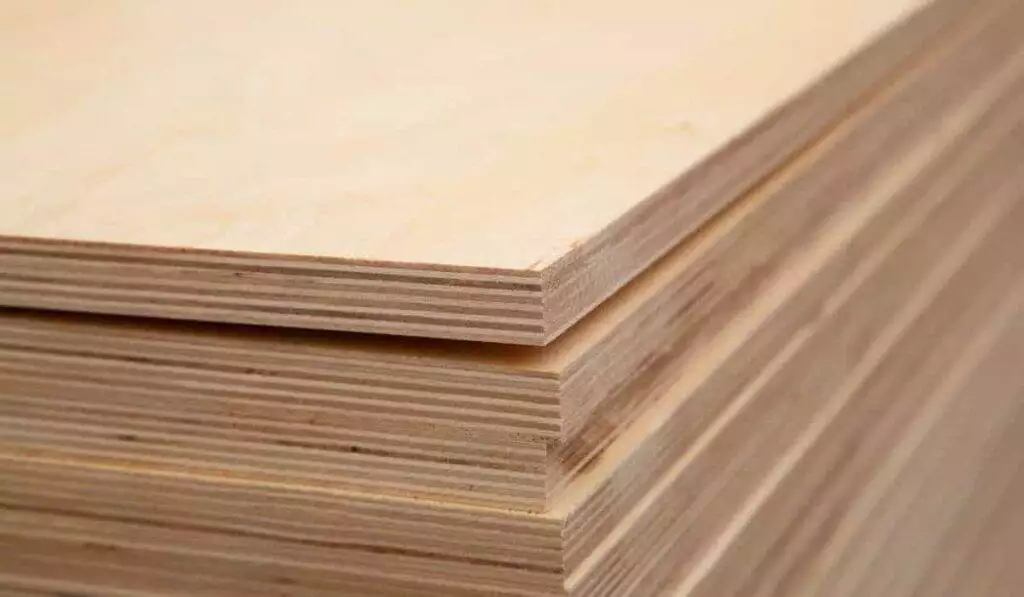

Marine plywood is a superior wood material that was created to operate effectively in the water. It is a class III plywood. Its name comes from its intended usage as a component of a boat’s hull—a structure constructed from numerous layers of oak planks joined together with watertight glue—to withstand prolonged exposure to water. Marine plywood is constructed to a premium level and will provide long-lasting waterproofing.

Marine Plywood Prices

This type of plywood usually ranges from ₱400.00 to ₱1,200.00 but sometimes it is even higher because this plywood is different.

| Details | Dimension | Unit | Price |

| Marine Plywood | (0.00625m x 1.2m x 2.44m) | pc | ₱427.16 |

| Marine Plywood | (0.0125m x 1.2m x 2.44m) | pc | ₱794.74 |

| Marine Plywood | (0.019m x 1.2m x 2.44m) | pc | ₱1,211.26 |

Advantages of Marine Plywood

Termite Infestation – A combination of adhesive that is made of formalin and termite-repellant chemicals is used to make marine plywood. The plywood is termite-proof as long as the chemicals remain effective as well as do not degrade. Any kind of wood can get infested with termites as the substances contained in them dissipate as time passes.

Waterproof – Plywood, by its inherent nature, has a propensity to soak up moisture, resulting in the disruption of the adhesive bond between veneers. On the other hand, marine plywood demonstrates resilience to humidity as well as moisture levels in mountainous regions, resorts, and coastlines for extended periods.

Durability and strength – For maximum durability, veneer layers are intersected to make plywood. High pressure and temperature strengthen it. Product shelf life depends on weather resistance and termite and borer resistance.

Disadvantages of Marine Plywood

Cost – The cost of marine plywood is generally greater compared to conventional plywood, primarily attributed to its superior quality and the incorporation of watertight adhesive.

Availability – Due to its superior quality, it is not easily accessible, making it difficult to locate if you reside in a rural region.

Weight – The incorporation of additional layers to enhance durability and resistance results in an increased weight compared to conventional plywood, hence posing challenges in terms of transportation during extensive projects.

Video about Marine Plywood

FAQs

Why choose Marine Plywood?

Marine plywood is popular because it performs well in damp environments. This plywood resists dampness, decomposition, and rotting, making it ideal for applications where other plywood may not last.

Does marine plywood possess strength?

Marine plywood is well-known for its durability and robustness. Due to its ability to endure substantial stresses, it is ideal for uses that need strong and dependable materials for construction.

Could marine plywood experience rotting?

Marine plywood resists degradation because it’s watertight. However, excessive moisture or incorrect installation may weaken its structure and cause deterioration.

Is it possible to apply paint to marine plywood?

Painting Marine Plywood is possible. Sanding and cleaning the surface improves paint adherence.

Is there water absorption in marine plywood?

Marine plywood exhibits a low capacity for water absorption resulting from its waterproof glue and superior overlay performance. The plywood is specifically designed to exhibit resistance against water infiltration, so guaranteeing the preservation of its durability and structural integrity even in the presence of moisture.